Introduction

Steel can be subdivided into carbon steel, low-carbon steel and high-carbon steel according to carbon content; steel also can be divided into hammered steel, cast steel, hot-rolled steel and cold drown steel according to different forming ways.

Roll forging is a process where round or flat bar stock is reduced in thickness and increased in length. Roll forging is performed using two cylindrical or semi-cylindrical rolls, each containing one or more shaped grooves. A heated bar is inserted into the rolls and when it hits a stop the rolls rotate and the bar is progressively shaped as it is rolled through the machine. The piece is then transferred to the next set of grooves or turned around and reinserted into the same grooves. This continues until the desired shape and size is achieved. The advantage of this process is there is no flash and it imparts a favorable grain structure into the workpiece.

Examples of products produced using this method include axles,rings, tapered levers and leaf springs.

Henan Metals & Minerals can supply all kinds of forging ring, hot rolling ring and welded flange which Dia 0.8M---6M big ring for our customers in Europe, USA and other countries.

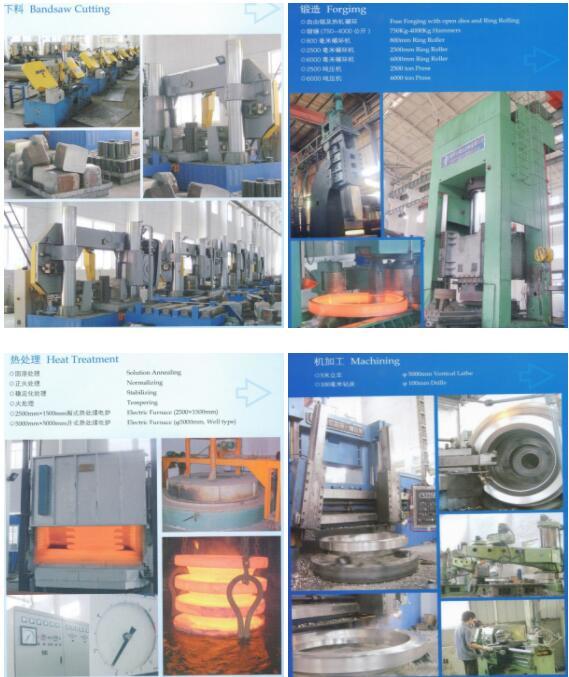

Henan Metals & Minerals has technical advantage in CNC ring roller from 800MM to 6000MM, 750Kg--4000Kg Hammers, 2500T and 6000T Press, surface and heat treatment, and all kinds of machining equipment, etc.

Henan Metals & Minerals own sets of advanced forging and processing equipments as well as testing machines,which provides reliable support of forging quality.We would give any possible assistance for being a reliable and stable partner of you.

Keywords:

Previous:

Next:

Message

Follow us

Henan Metal & Minerals I/E Co., Ltd.

welcomes friends from all over the world. We are always here waiting for your consultation.

Message

If you want to know more about our products, send a message to us, and we will get back to you within 24 hours.

Copyright © Henan Metals & Minerals I/E Co.,Ltd. All rights reserved